Briefly

- Wandercraft, the French firm identified for its medical exoskeletons, has entered the sphere of humanoid robotics.

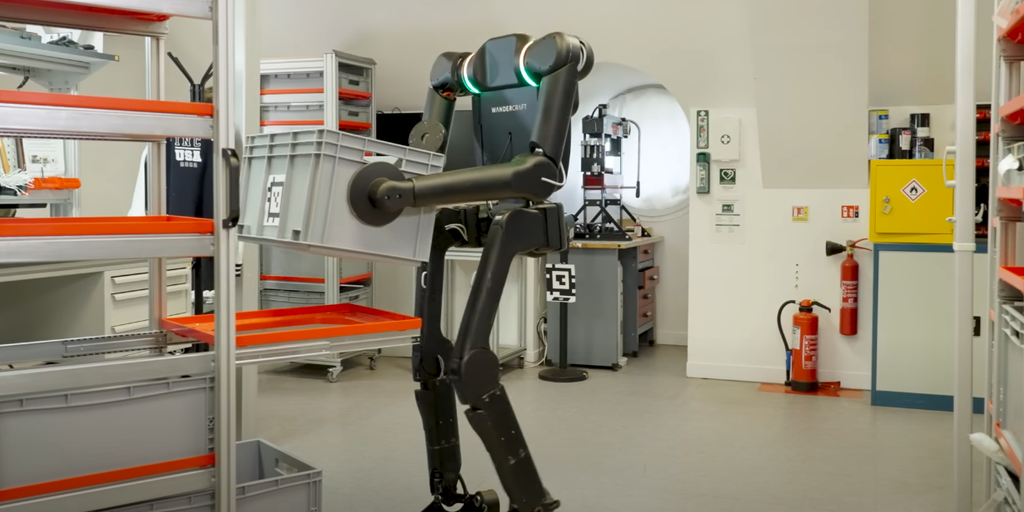

- In-built simply 40 days utilizing the identical core expertise as its exosuits, Wandercraft stated Calvin 40 is already being examined in industrial environments.

- The robotic omits humanlike options together with a head and arms, and focuses on sensible, hazardous duties which are tough or harmful for human staff.

After capturing world consideration on the 2024 Olympics, the place its exoskeleton helped a paraplegic man stroll, Paris-based Wandercraft is now shifting its focus from wearable robotics to totally autonomous humanoid robots.

Wandercraft’s new humanoid robotic, Calvin 40—so named as a result of it was reportedly inbuilt simply 40 days—is already being examined on manufacturing unit flooring. As Wandercraft CEO Matthieu Masselin defined, the fast development of Calvin 40 was enabled by repurposing expertise from the corporate’s exoskeletons.

“You see all these humanoid robots in all places—Tesla, Determine AI, firms in China—and for us, it’s the identical expertise we’ve been creating for the final 10 years,” Masselin advised Decrypt in an interview. “It felt so pure for us.”

Masselin stated the corporate was additionally capable of produce Calvin 40 so rapidly partially as a result of it omitted the pinnacle and hand options sometimes present in humanoid robots, reminiscent of Tesla’s Optimus or Determine AI’s Determine 02.

“We’re not centered on including a head, as a result of it doesn’t assist with navigation, the identical goes for arms, arms are very fragile,” he stated. “We consider we’ve a humanoid robotic that may carry the heaviest payload.”

As an alternative of arms, Calvin 40 makes use of padded, arm-like grippers with flat round panels to choose up packing containers and crates.

Masselin stated the pinnacle and arms have been additionally not noted to keep away from the uncanny valley impact, a discomfort folks really feel when interacting with robots that seem virtually—however not fairly—human.

“Expressive manipulation issues in houses or sure conditions, however in our case, an easier design is simply as efficient,” he stated.

Humanoid robots have surged in recognition in recent times. In response to a February 2024 report by Goldman Sachs, the worldwide marketplace for humanoid robots is predicted to achieve $38 billion by 2035, pushed by advances in AI and automation.

Whereas some humanoid robotic builders have centered on social interplay or private help, Masselin stated Wandercraft’s design selections emphasize bodily labor in areas constructed for folks.

“So many environments are constructed for the human kind that it’s tough to deal with all wants with out mimicking it,” he stated, including that the corporate is working with companions to deploy Calvin 40 in “hazardous” or hard-to-staff duties.

“One of many largest differentiators of our expertise is that it was initially designed—and continues to be used—to develop an exoskeleton, which is a robotic that carries a human being as much as 220 kilos,” Masselin stated. “Meaning the expertise has to deal with that form of payload.

In response to Wandercraft, Calvin 40 can carry payloads of as much as 40 kilograms, or about 88 kilos—practically twice as a lot as comparable robots like Tesla’s Optimus or Determine AI’s Determine 02, that are rated to hold round 45 kilos.

“No different humanoid robots can carry that a lot, by a large margin—largely as a result of they focus a lot on arms,” Masselin stated.

In response to Wandercraft, the Calvin 40 is at present being examined by French multinational automotive producer Renault Group, however he declined to offer a value for the robots.

By reusing core expertise from its exoskeletons, Masselin believes Wandercraft can skip the experimental section and give attention to deploying robots in industrial environments.

“We work with our companions to grasp their wants—the place they’ve duties which are too tough, too harmful, or onerous to rent for,” he stated. “The query turns into: Can we provide a safer resolution for hazardous jobs in order that staff can give attention to high quality and craftsmanship? That’s the technique.”

Edited by Andrew Hayward

Usually Clever Publication

A weekly AI journey narrated by Gen, a generative AI mannequin.